Bone Models

Custom Clear Acrylic Or Bone White Models

Both our clear acrylic bone models and opaque bone white models can be used in sales kits and for patient education. Our models are ideal for launching your newest products or re-launching existing products.

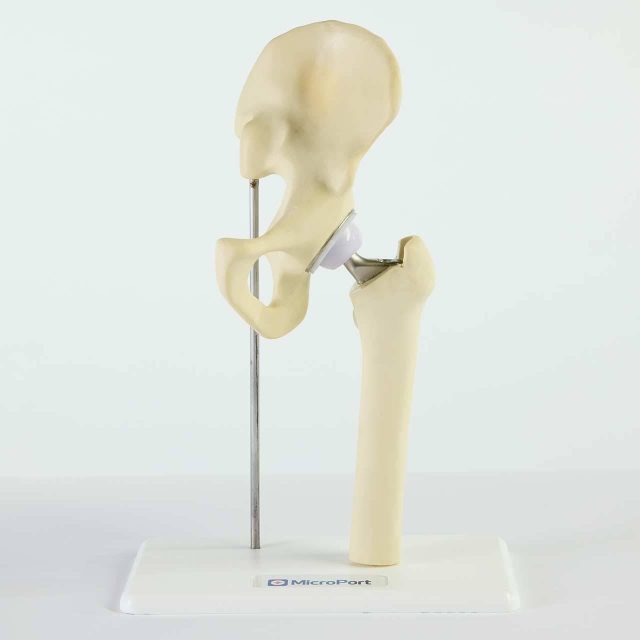

Clear Acrylic Models With Embedded Implants

Our bone models are made with acrylic that is clear as water and embedded with your implants. If you can provide your implant, we have the capability to take your bone models to the next level. Implant replicas can also be embedded in place of the actual implant.

These models can be used for patient education and included in your sales kits. Every bone model is custom-made to fit your company’s standard implant size specifications.

Embedded implant replicas can save huge expenses and reserve implants for clinical use during product launches.

Becca — Product Manager

Frequently Asked Questions

How long will it take?

Each project is unique. For complex projects involving design and development, we will first schedule a virtual meeting with you and then provide a “scope of work” document detailing a timeline for the steps to completion.

Most projects require prototype approval, which can occasionally lead to delays depending on your company’s approval process. Changes to the scope of work can also delay the project, so a thorough understanding of the project upfront is critical.

Our team will work with you throughout the process to ensure unnecessary delays don’t occur.

How much will it cost?

We quote all of our work based on time and materials. As a general rule, the first model is always the most expensive model.

Who does the work and where is it done?

Phil and his team are all experienced in the creation of 3D printing, masters, molds, high-quality paintwork, and finishes. We have made bone models and implant replicas for years at our on-site facilities with a variety of equipment and processes located in Warsaw, Indiana.

Any outside work is completed in the USA, generally in close proximity to our Indiana location to save time and reduce shipping expenses.

Can you work with an engineering file?

Yes, we routinely work with Unigraphics, Solidwork, Parasolid, and mesh files provided by customers and have experienced orthopedic engineering resources to assist you.

Starting with your files is the easiest way for us to begin work.

The Process

How Does it Work?

Define Project Scope

We start with your description of the need and create a written project scope. The scope of work can be done in person or virtually.

Design & Development

Our design & development team will create a rendering of how your product will work in your target environment.

Prototype

With most of our projects, a prototype is produced from the approved renderings generated during the design & development phase.

Production

After approval of the prototype, we will fabricate the predetermined quantity of your model, sales kit, exhibit, educational tools, or other solution.

Continued Support

Our production system ensures each customer has a designated cart to ensure reproducibility and easy future reorders and support.